In an era where security concerns are increasingly prevalent across military, civilian, and private sectors, the demand for reliable protection against ballistic threats has never been higher. From soldiers on the battlefield to executives in high-risk environments and fleet managers safeguarding valuable assets, bulletproof technology stands as a critical line of defense. This comprehensive guide delves into the science, materials, standards, and diverse applications of modern bullet-resistant solutions, offering insights for professionals and enthusiasts alike.

What Exactly is Bulletproof Technology?

While the term “bulletproof” is commonly used, it’s more accurate to describe these solutions as “bullet-resistant.” No material is truly impervious to all threats under all conditions. Instead, bulletproof technology encompasses a range of materials and engineering principles designed to absorb and dissipate the kinetic energy of a projectile, preventing penetration and minimizing behind-armor trauma.

The core principle involves either:

– Deforming or shattering the incoming bullet.

– Catching and “decelerating” the bullet within layers of high-strength material.

– A combination of both mechanisms.

Effective bullet-resistant solutions are engineered to withstand specific types of ammunition at particular velocities, as defined by recognized ballistic standards.

The Science Behind Ballistic Resistance: Key Materials and Innovations

The evolution of bulletproof technology is a story of ongoing material science advancements, moving from heavy steel plates to sophisticated, lightweight composites and ceramics.

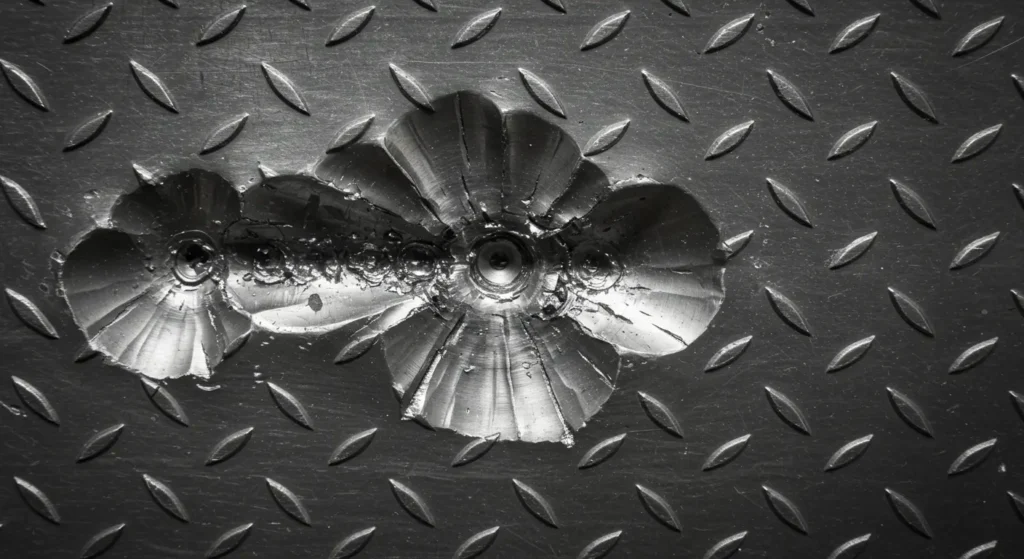

Traditional Armor: The Enduring Strength of Steel

For decades, specially treated steel alloys, like AR500 (Abrasion Resistant steel with a Brinell hardness of around 500), have been the workhorse of ballistic protection.

– How it works: High-hardness steel causes projectiles to deform, shatter, or ricochet upon impact. The steel itself absorbs a significant amount of energy.

– Pros: Relatively cost-effective, widely available, durable, and effective against a broad range of threats, including multiple hits.

– Cons: Its primary drawback is weight. Protecting large areas or ensuring personnel mobility with steel armor can be challenging.

Advanced Composites: Lightweight and High-Performance

The quest for lighter protection led to the development of advanced composite materials, revolutionizing personal and vehicular armor.

– Aramid Fibers (e.g., Kevlar®, Twaron®): These are strong, synthetic fibers with exceptional tensile strength-to-weight ratios. They are woven into fabrics and layered.

– How it works: When a bullet strikes aramid fiber layers, the fibers stretch and “catch” the projectile, distributing its energy across a wider area, much like a net stopping a ball.

– Ultra-High Molecular Weight Polyethylene (UHMWPE) (e.g., Dyneema®, Spectra Shield®): UHMWPE fibers are even lighter than aramids and boast incredible strength. They are typically arranged in a unidirectional manner and bonded into rigid or semi-rigid panels.

– How it works: Similar to aramids, UHMWPE absorbs energy through fiber deformation and delamination of layers, effectively slowing and trapping the bullet.

– Pros: Significant weight reduction compared to steel for similar protection levels, flexibility (for soft armor), and good multi-hit capability in some configurations.

– Cons: Generally more expensive than steel, can be susceptible to degradation from UV light and moisture if not properly encased, and less effective against armor-piercing rounds on their own.

Ceramic Armor: Defeating High-Velocity Threats

For protection against high-velocity rifle rounds and armor-piercing ammunition, ceramic materials are often indispensable.

– Materials: Common ceramics include Alumina (Aluminum Oxide), Silicon Carbide (SiC), and Boron Carbide (B4C), with Boron Carbide being the lightest and hardest, but also the most expensive.

– How it works: Ceramic plates are extremely hard. Upon impact, the ceramic layer fractures the tip of the projectile and erodes its mass. The ceramic itself shatters in the process, absorbing a large amount of the bullet’s kinetic energy. A backing material (often composite or steel) is essential to catch the fragmented projectile and remaining ceramic pieces.

– Pros: Excellent protection against high-level threats relative to their weight.

– Cons: Can be brittle and typically offer less multi-hit capability in the immediate impact zone compared to steel or some composites. Higher cost.

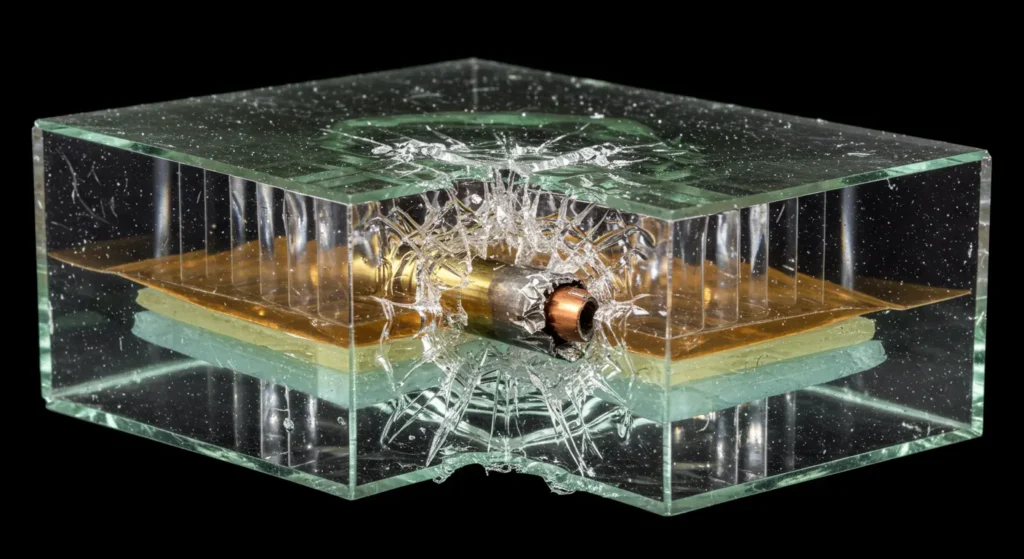

Transparent Armor: Clarity Under Fire

Protecting against ballistic threats while maintaining visibility is crucial for vehicle windows, vision blocks, and architectural applications.

– Materials: Modern transparent armor is usually a multi-layer laminate. This can consist of:

- Glass-Clad Polycarbonate: Layers of glass on the exterior strike face, with multiple layers of polycarbonate and specialized interlayers bonded together.

- All-Polycarbonate Laminates: Multiple layers of polycarbonate bonded together.

– How it works: The outer glass layer (if present) helps to flatten or break up the bullet. The subsequent polycarbonate layers absorb and dissipate the energy through deformation and delamination, preventing penetration.

– Pros: Provides visibility while offering significant ballistic protection.

– Cons: Can be very thick and heavy, especially for higher protection levels. Optical distortion, delamination over time, and cost are also considerations.

Understanding Protection Levels: NIJ Standards and Beyond

To ensure bulletproof technology performs as expected, standardized testing and certification are vital. The most widely recognized standard in the United States, particularly for personal body armor and law enforcement applications, is from the National Institute of Justice (NIJ).

– NIJ Standard 0101.06 (for Body Armor) and NIJ Standard 0108.01 (for Ballistic Resistant Protective Materials): These standards classify armor into different levels based on the type and velocity of ammunition it can defeat.

– Level IIA, II, and IIIA: Designed to stop common handgun rounds. Level IIIA is the most common for soft body armor, capable of stopping .357 SIG and .44 Magnum rounds.

– Level III: Protects against 7.62mm FMJ rifle rounds (e.g., AK-47 type rounds). Typically requires hard armor plates (steel, ceramic, or composite).

– Level IV: The highest NIJ rating for personal armor, designed to stop .30-06 M2 armor-piercing (AP) rifle rounds. This almost always requires ceramic-faced composite plates.

Other international standards, such as NATO’s STANAG (Standardization Agreement), govern military ballistic protection for vehicles and personnel. It’s crucial for users to select armor rated for the specific threat levels they are likely to encounter.

Applications of Bulletproof Technology: Protecting Assets and Lives

The applications of bulletproof technology are diverse, spanning military, law enforcement, and civilian sectors.

Military and Law Enforcement

– Armored Vehicles: From Mine-Resistant Ambush Protected (MRAP) vehicles and infantry fighting vehicles to up-armored patrol cars, **bulletproof technology** is essential for crew survivability. This involves integrating opaque and transparent armor solutions.

– Personal Body Armor: Ballistic vests, helmets, and tactical shields are standard issue, significantly reducing casualties from gunfire and fragmentation.

– Aircraft and Naval Vessels: Critical areas of aircraft and ships are often armored to protect crew and sensitive systems.

Civilian Armored Vehicles

The demand for civilian armored vehicles is growing, driven by security concerns for:

– Executive Protection: High-net-worth individuals, diplomats, and corporate executives utilize discreetly armored sedans and SUVs.

– Cash-in-Transit (CIT) Vehicles: Specialized vehicles for transporting currency and valuables rely heavily on robust armoring.

– Fleet Managers: Companies operating in high-risk areas may opt for armoring fleet vehicles to protect personnel and assets. Vehicle armoring solutions range from partial protection to full B6/B7 level armoring.

Architectural and Structural Protection

Bulletproof technology also extends to fixed structures:

– Secure Rooms and Panic Rooms: Offering a protected space within a building.

– Guard Booths and Checkpoints: Protecting security personnel.

– Banks, Government Buildings, and Embassies: Utilizing bullet-resistant glass, doors, and wall panels to enhance security.

Key Considerations When Implementing Bulletproof Technology

Choosing and implementing bulletproof technology requires careful consideration of several factors:

– Threat Assessment: What specific types of projectiles and threat levels are you protecting against? This is the most critical first step.

– Weight vs. Protection: This is a constant trade-off. Heavier armor generally offers more protection but can impact vehicle performance, payload capacity, or individual mobility. Lightweight armor solutions often come at a premium.

– Cost: The price of bulletproof technology varies dramatically based on materials, protection level, and coverage area.

– Integration and Installation: Proper installation is paramount. Even the best materials can fail if not correctly integrated into a vehicle or structure. For vehicles, this includes ensuring no ballistic gaps exist around doors, windows, and seams.

– Multi-Hit Capability: How well does the armor withstand multiple impacts in close proximity?

– Maintenance and Lifespan: Some materials, particularly composites and transparent armor, can degrade over time due to environmental exposure (UV, moisture, temperature extremes) or impacts. Regular inspection and adherence to manufacturer guidelines are important.

The Future of Bulletproof Technology: What’s Next?

The field of bulletproof technology is continuously evolving, with researchers pushing the boundaries of material science for even better protection:

– Nanomaterials: Materials like graphene and carbon nanotubes show promise for creating exceptionally strong yet lightweight armor.

– Liquid Armor / Shear Thickening Fluids (STFs): These fluids remain liquid under normal conditions but become rigid almost instantaneously upon impact, absorbing and dispersing energy. They could be integrated with conventional fibers like Kevlar to enhance performance.

– Magnetorheological Fluids: Similar to STFs, these fluids change viscosity when exposed to a magnetic field, offering potential for adaptive armor.

– Advanced Composites and Hybrids: New fiber formulations and hybrid material systems (e.g., ceramic-metal-composite sandwiches) aim to optimize protection while minimizing weight and thickness.

– Smart Armor Systems: Future armor could incorporate sensors to detect impacts, assess damage, and even provide medical telemetry.

Conclusion: A Commitment to Safety and Security

Modern bulletproof technology represents a sophisticated and rapidly advancing field, crucial for safeguarding lives and assets in an unpredictable world. From the battle-tested strength of steel to the lightweight resilience of advanced composites and the formidable stopping power of ceramics, these materials provide varying levels of protection tailored to diverse threats and applications.Understanding the underlying science, recognized standards, and key implementation considerations allows military/security professionals, civilian fleet managers, and vehicle enthusiasts to make informed decisions. As research continues to unlock new materials and innovative designs, the future promises even more effective, lighter, and adaptable bulletproof technology, reinforcing our commitment to safety and security in all domains.